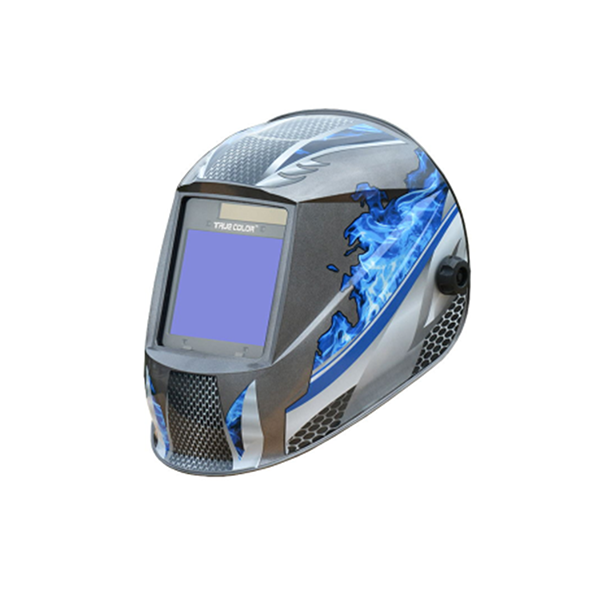

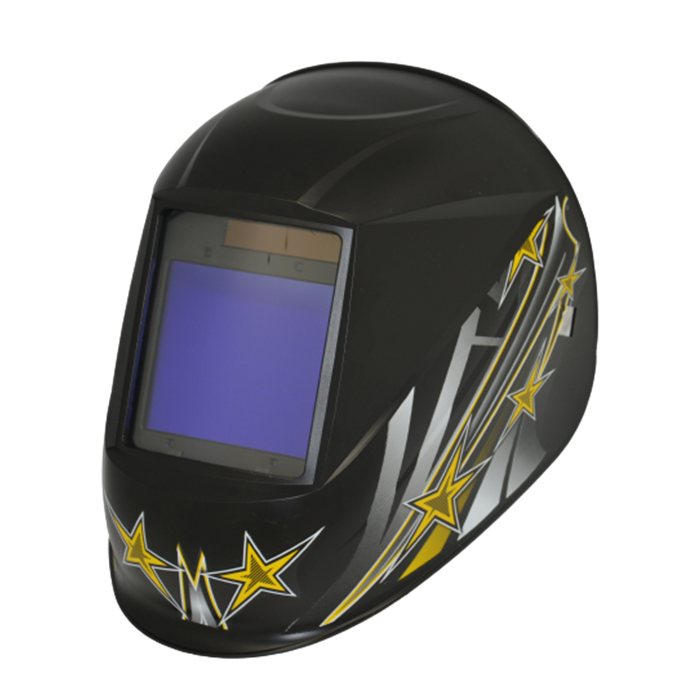

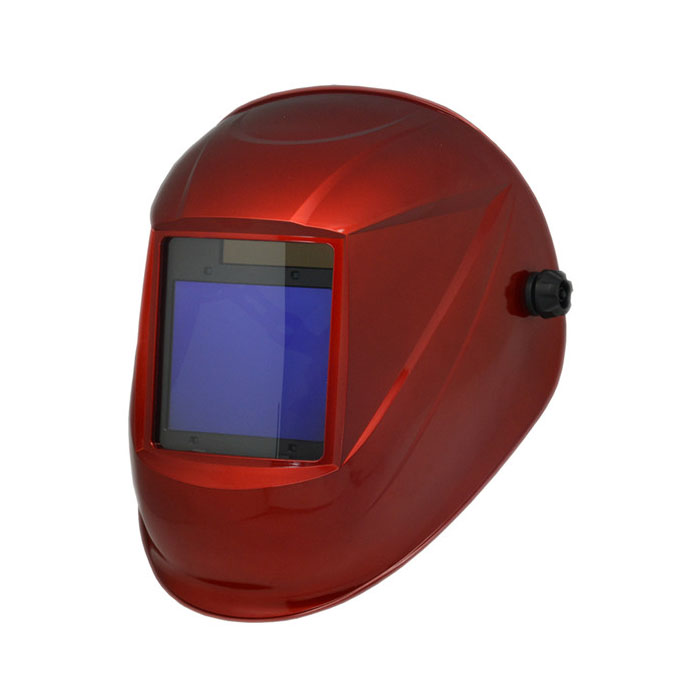

Ifestile enkulu yeSolar Automatic Photowelding Helmet

Inkcazo

I-Auto Darkening i-helmet ye-welding yenzelwe ukukhusela amehlo akho kunye nobuso kwiintlantsi, i-spatter, kunye nemitha eyingozi phantsi kweemeko ze-welding eziqhelekileyo. Isihluzo sokwenza ubumnyama ngokuzenzekelayo sitshintsha ngokuzenzekelayo ukusuka kwimeko ecacileyo ukuya kwindawo emnyama xa i-arc ibethelwa, kwaye ibuyela kwimeko ecacileyo xa i-welding iyeka.

Iimbonakalo

♦ Isigcina-ntloko se-welding yeengcali

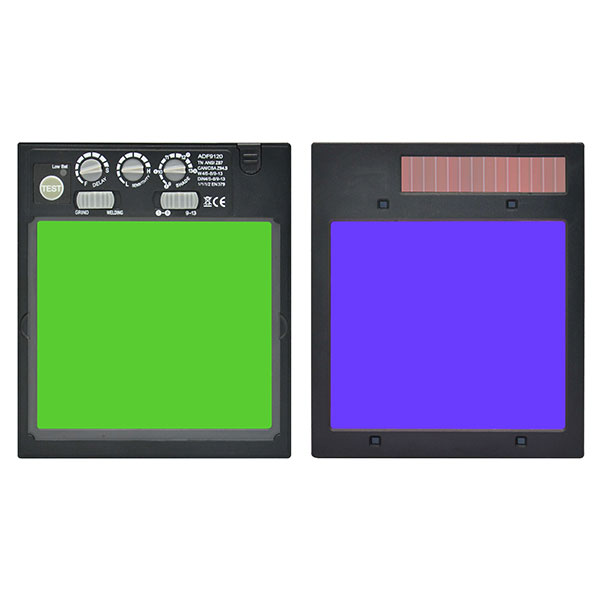

♦ Iklasi ye-Optical : 1/1/1/1 okanye 1/1/1/2

♦ Umbono omkhulu ngakumbi

♦ Ukuwelda kunye nokuSila nokusika

♦ Ngemigangatho ye-CE, ANSI,CSA,AS/NZS

Iinkcukacha zeemveliso

| IMODE | TN360-ADF9120 |

| Iklasi ye-Optical | 1/1/1/1 okanye 1/1/1/2 |

| Ubungakanani besihluzi | 114×133×10mm |

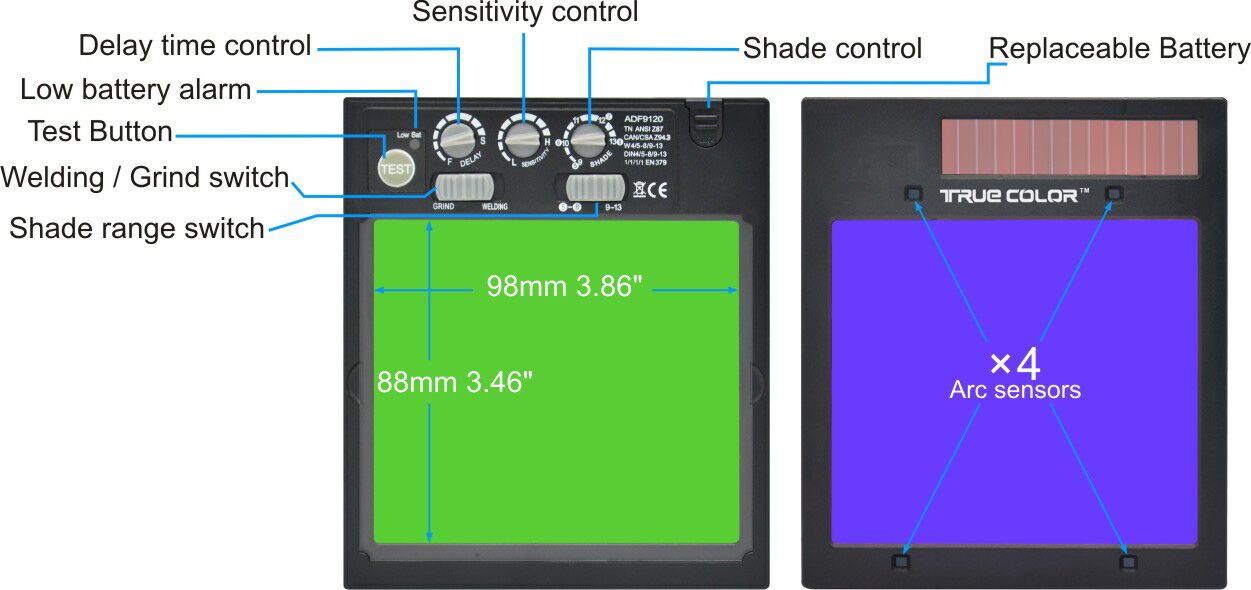

| Jonga ubukhulu | 98×88mm |

| Umthunzi wemeko yokukhanya | #3 |

| Umthunzi wemeko emnyama | Umthunzi oguquguqukayo we-DIN5-8/9-13, useto lweQhubhu lwangaphakathi |

| Ukutshintsha ixesha | 1/25000S ukusuka ekuKhanyeni ukuya kuMnyama |

| Ixesha lokubuyisela ngokuzenzekelayo | 0.2 S-1.0S Ukukhawuleza ukuya kwi-Slow, uhlengahlengiso olungenasinyathelo |

| Ukulawula uvakalelo | Phantsi ukuya phezulu, uhlengahlengiso olungenanyathelo |

| Uluvo lweArc | 4 |

| Ephantsi TIG Amps Rated | AC/DC TIG,> 5 amps |

| UKUSILA umsebenzi | Ewe (#3) |

| Uluhlu lomthunzi wokusika | Ewe (DIN5-8) |

| Ukuzijonga i-ADF | Ewe |

| Ibhethi ephantsi | Ewe (i-LED eBomvu) |

| Ukhuseleko lwe-UV / IR | Ukuya kuthi ga kwi-DIN16 ngalo lonke ixesha |

| Ubonelelo olunamandla | Iiseli zeSola kunye nebhetri yeLithium eTshintshwayo ( CR2450) |

| Vula/cima | Okuzenzekelayo ngokupheleleyo |

| Izinto eziphathekayo | Inqanaba lempembelelo ephezulu, inayiloni |

| Iqondo lokushisa elisebenzayo | ukusuka -10℃–+55℃ |

| Ukugcina iqondo lokushisa | ukusuka -20℃–+70℃ |

| Iwaranti | iminyaka eyi-2 |

| Umgangatho | CE EN175 & EN379, ANSI Z87.1, CSA Z94.3 |

| Uluhlu lwesicelo | I-Stick Welding (SMAW); I-TIG DC∾ TIG Pulse DC; TIG Pulse AC; MIG/MAG/CO2; I-MIG/MAG Pulse; Ukusika i-Plasma Arc (PAC); I-Plasma Arc Welding (PAW); Ukusila. |

1. Phambi kokuWelding

1.1 Qinisekisa ukuba iifilimu ezikhuselayo zangaphakathi nangaphandle ziyasuswa kwiilensi.

1.2 Tshekisha ukuba iibhetri zinamandla aneleyo okusebenzisa isigcina-ntloko. I-cartridge yokucoca ingahlala kwiiyure ze-5,000 zokusebenza ezixhaswe yibhetri ye-lithium kunye neeseli zelanga. Xa amandla ebhetri ephantsi, isalathisi se-LED yeBattery ePhantsi siya kukhanya. Ilensi yekhatriji yokucoca isenokungasebenzi kakuhle. Buyisela iibhetri endaweni yazo (jonga iBattery yokuLondoloza).

1.3 Khangela ukuba i-arc sensors icocekile kwaye ayivalwanga luthuli okanye inkunkuma.

1.4 Jonga ukuxinana kwebhanti yentloko phambi kokusetyenziswa ngakunye.

1.5 Hlola onke amalungu asebenzayo phambi kokuba uwasebenzisele iimpawu zokuguga okanye zokonakala. Naziphi na iindawo ezikrweliweyo, eziqhekekileyo, okanye ezinemingxuma kufuneka zitshintshwe ngokukhawuleza phambi kokuba zisetyenziswe kwakhona ukunqanda ukwenzakala kakhulu.

1.6 Khetha inombolo yomthunzi oyifunayo xa ujika iqhina lomthunzi (Ukubona iSikhokelo soMthunzi). Okokugqibela, qiniseka ukuba inombolo yomthunzi luseto oluchanekileyo lwesicelo sakho.

Phawula:

☆SMAW-Shielded Metal Arc Welding.

☆TIG GTAW-Gas Tungsten Arc (GTAW)(TIG).

☆MIG (Enzima) -MIG kwiintsimbi ezinzima.

☆I-SAM Ikhuselwe iSemi-Automatic Arc Welding.

☆ MIG (Ukukhanya) -MIG kwii-alloys ezikhanyayo.

☆PAC-Plasma Arc Ukusika

1. Ukucoca kunye nokubulala iintsholongwane: Coca imiphezulu yezihluzi rhoqo; musa ukusebenzisa izisombululo zokucoca ezinamandla. Hlala ugcina izivamvo kunye neeseli zelanga zicocekile usebenzisa ithishu/ilaphu elicocekileyo. Ungasebenzisa utywala kunye nekotoni ukusula.

2. Sebenzisa i-detergent engathathi hlangothi ukucoca igobolondo ye-welding kunye ne-headband.

3. Tshintsha iipleyiti zokukhusela zangaphandle nangaphakathi ngamaxesha athile.

4. Musa ukuntywilisela ilensi emanzini okanye naluphi na ulwelo. Ungaze usebenzise iziqholo, izinyibilikisi okanye izicoci ezisekwe kwioyile.

5. Musa ukususa isihluzo esizenza mnyama kwisigcina-ntloko. Ungaze uzame ukuvula isihluzo.